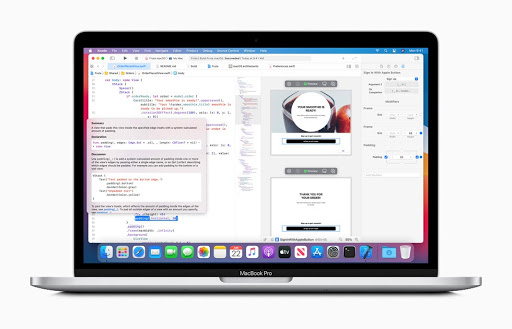

Xcode 11 is a fundamental developing tool that includes everything needed to create amazing apps for all Apple platforms. It consists of the latest SDKs for macOS 10.15, iOS 13, iPadOS 13, watchOS 6, and tvOS 13. Xcode 11 includes SwiftUI, a framework that provides views, controls, and layout structures for declaring an app’s UI.

Learn more about Swift Programming Language

SwiftUI is the latest way to declare user interfaces for an iOS platform and create amazing and dynamic apps faster than ever before. Swift eliminates common programming errors by adopting modern programming patterns. SwiftUI eliminates entire classes of unsafe code and adds great new features to make sharing code across Apple’s platforms even easier.

- Variables are always initialized before use.

- Arrays and integers are checked for overflow

- Memory is automatically managed.

- Ability to exclusively access memory guards against many programming mistakes.

“Swift has been years in the making, and it continues to evolve with new features and capabilities”. At Apple WWDC20 it was mentioned that their goals for Swift are ambitious and that they are eager to see what developers create with it.

SwiftUI introduced developers to a modern UI framework that can help build sophisticated and agile app UIs. Bringing together the global Apple developer community of more than 23 million in a phenomenal and virtual way, Apple announced a plethora of latest enhancements in the swift programming language.

Latest Enhancements in SwiftUI

1. Redesigned widgets

With redesigned widgets on the Home Screen pages, users can experience the developer’s widget every time they look at their device. With new extensions to the SwiftUI API, developers can use the same code to build a widget for iOS, iPadOS, and macOS simultaneously. SwiftUI can be used to create custom complications for WatchOS.

2. Easy Sharing

Swift Package Manager enables easy sharing of Asset Catalog bundles and localizations. .matchedGeometryEffect to provide fluid animations inside of a grid of UI elements. Custom fonts shall automatically scale with dynamic type changes.

3. Extended Use Cases

New open-source packages have been introduced for Numerics, ArgumentParser, and System making Swift a great language for more use cases. It will be able to support basic math functions as well as complex numbers.

4. App-structure APIs

SwiftUI now contains app-structure APIs for all Apple platforms, e.g. @main, @SceneBuilder, Settings etc and WindowGroup to manage windows platform independently.

5. Extended SwiftUI Capabilities

Now developers can write an entire app in SwiftUI using the life cycle API and share it across all Apple platforms. struct BookClubApp: App

6. Simplified App Upgrade

Developers already working with swift can now easily add features to their existing code. Lazy API (Lazy[V|H]Stack) can be used to reduce memory footprint and offer smooth navigation for enormous amounts of data.

Further Reading:

- Apple reveals new developer technologies to foster the next generation of apps

- Github: What’s new in SwiftUI

Related Technology Blogs:

Knowledge thats worth delivered in your inbox